Liquid Filters.

From utility water used during manufacturing processes to sterile ingredient water, our liquid filtration solutions will help preserve the integrity of your product.

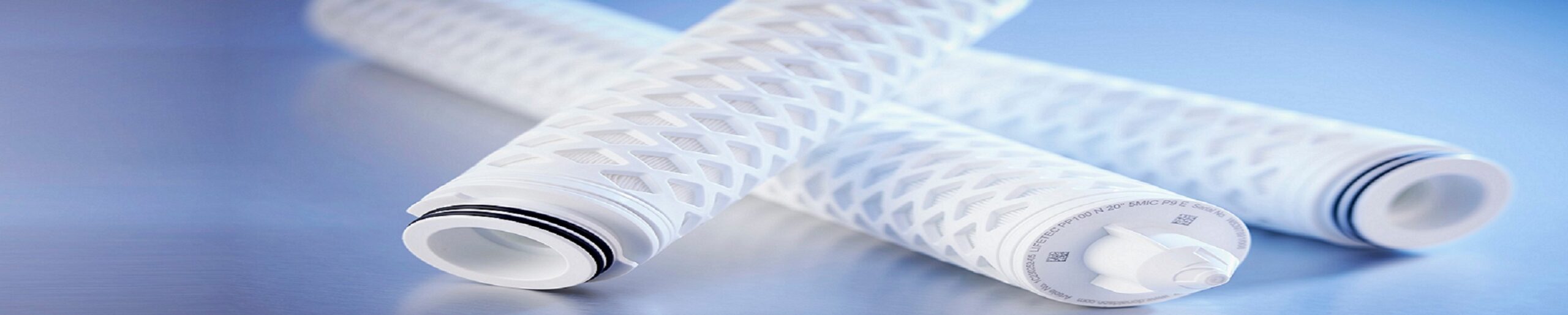

Replacement Liquid Filters

We offer filter elements to protect the integrity of your liquids and utilizes cartridge filter elements to enhance product performance.

Meltblown Polypropylene

Water Grade Meltblown Polypropylene Filter Cartridges:

- A gradient density structure provides for low pressure drop and high dirt holding capacity.

- All polypropylene construction presents excellent compatibility with a wide range of chemicals.

BB-Series Meltblown Polypropylene

Water Grade Meltblown Polypropylene Filter Cartridges:

- A gradient density structure provides for low pressure drop and high dirt holding capacity.

- All polypropylene construction presents excellent compatibility with a wide range of chemicals.

- Resists contaminant unloading, even at elevated differential pressures.

- Easy cartridge incineration and disposal.

- Free of additives, wetting agents, binders and silicone.

Wound Depth Filter cartridges

Wound Depth Filter cartridges::

- Available in a wide variety of lengths and micron ratings from 9.75 to 50 inches and 0.5-400 µ

- Medias to fit all applications including: FDA polypropylene, bleached cotton, FDA bleached cotton, natural cotton, polyester, nylon and glass

- Core materials include: polypropylene, 304 & 316 stainless steel, tin and glass

- Performance-enhancing end-configurations available to fit every process requirement

Standard Mesh Liquid Filter Bag Specifications:

- Micron ratings from 1 to 1500

- All industry-standard and custom sizes available

- High flow/low pressure drop media

- Surface-retention filtration

- Wide chemical compatibility

- Sewn construction

- Handles standard on all bags

- Non-fiber shedding

- High removal efficiency

- Temperature ratings to 400ºF (204ºC)

- Silicone-free construction

- Economical removal of non-deformable contaminants

- Choice of steel or molded plastic snap seal rings

- Meet FDA regulations for contact under Title 21, Section 177.1520