Silt Density Index (SDI) Test

Silt Density Index (SDI) Test

For wine and beer manufacturers, filtration is a critical process in ensuring the highest quality of the final product. Filtration systems remove any impurities from the water used in production, but the performance of the system depends on its layout.

The filtration layout refers to the arrangement of filters in the system, including the type, order, and placement of filters. The layout must be carefully designed to ensure the effective removal of impurities while maintaining the optimal flow rate and minimizing maintenance costs.

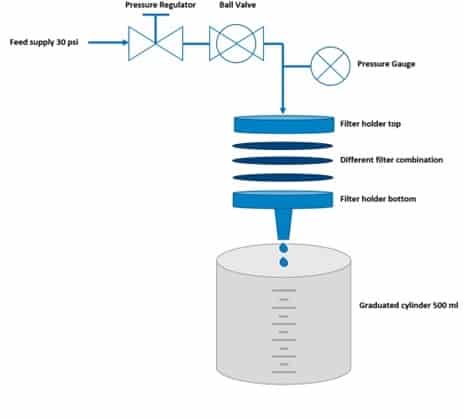

That’s where the Silt Density Index (SDI) test comes in. It is a valuable tool for wine and beer manufacturers to determine the optimal filtration layout for their system. By performing the SDI test at different stages of the filtration process, operators can identify where adjustments are needed to improve filter performance and optimize the layout of filters in the system.

For example, if the SDI value is high at the beginning of the treatment process, it may indicate that the pre-treatment filters need to be adjusted or replaced. Similarly, if the SDI value is high at the end of the treatment process, it may suggest that the final filters need attention.

What is the SDI Test?

What is the SDI Test?

By using the SDI test, wine and beer manufacturers can determine which filters are performing effectively and which may need adjustment or replacement. This is particularly

important for the final filter, which plays a crucial role in removing any impurities that could affect the taste and quality of the final product.

In addition, the SDI test can help wine and beer manufacturers anticipate the extension of filter life. By simulating different types of pre-filters, operators can determine the best layout of filters in the system, allowing for extended filter life and reduced maintenance costs.

Case Study

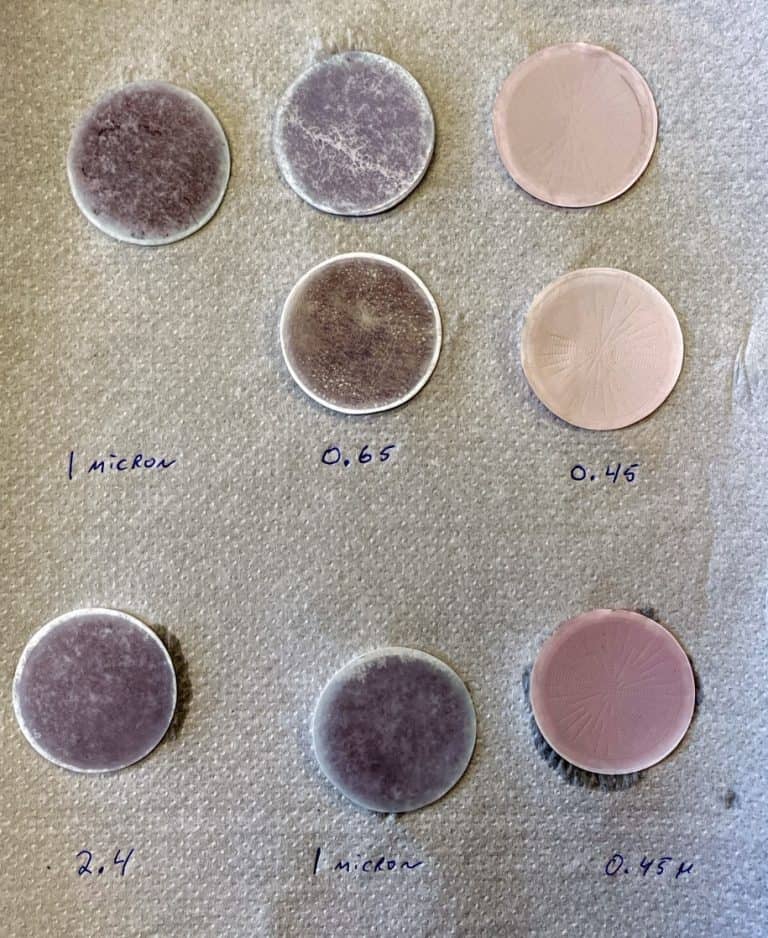

One example of the benefits of using the SDI test is a large wine manufacturer in Quebec .

Their final filter with a 0.45-micron rating was blocking very fast, affecting the quality of their wine.

By using the SDI test and simulating different types of pre-filters, they were able to determine the best layout of filters in their system. This allowed them to anticipate an extension of the 0.45-micron filter life 5 to 10 times, resulting in improved quality and reduced maintenance costs.

Conclusion

Conclusion

In conclusion, the SDI test is a valuable tool for wine and beer manufacturers to optimize their filtration layout. By identifying where adjustments are needed, operators can improve filter performance and anticipate filter life extension, resulting in improved product quality and reduced maintenance costs. A well-designed filtration layout ensures effective removal of impurities while maintaining the optimal flow rate and minimizing maintenance costs, resulting in higher quality and more cost-effective wine and beer production.